Quantitative loading system

The raw materials used in the petroleum and chemical industry are mostly liquid media, and so very strict requirements are placed on them in terms of measurement accuracy, safety, ease of operation and maintenance, as well as automation. To meet the increasingly higher requirements of users, Our Company has developed several load systems to meet the demand of different users.

The KP2.0 intelligent ration loading control and management system developed by Shanghai Keypoint Controls Co., Ltd. is a completely new loading control and management system, which gets ride of the technical defects of previous loading systems. As an information-based intelligent liquid loading product integrating multiple technical innovations, the product is capable of measuring, controlling, processing and information-based management. In addition, it integrates cutting-edge hardware technologies, measuring technologies, software technologies, data application technologies and data management technologies, so it allows for accurate, safe, intelligent, and information-based application during the loading measurement process

1.Several advanced technologies are adopted for the system, which integrates functions like communication, control, safety protection, data management, authorization, and data mining, and is able to deliver complete loading measurement solutions for users.

2.The system is based on module hardware and standard software: through module-based design of the internal fittings of batch controller, the onsite core controlling device, the expandability and applicability of the system are both improved drastically. More fittings may be added according to the actual requirements of the onsite loading instrument, so as to achieve effective configuration, and meet the practical application requirements of customers. The software has a standard module design. Configuration of the software module is subject to the level of the user. This way, various control and management functions are realized.

3.The distributed loading network system: with distributed configuration of the entire loading system, the controllable failure rate and application range of the system are significantly increased. Power supply to the system could be cut off by only cutting the failure equipment from the corresponding distributed network. This way, the effective operation of other systems is guaranteed.

4.Several safety control measures: several safety mechanisms are provided in the onsite batch controllers and software operation system design. No action is to be executed without authorization. This way, safety of onsite workers and equipment, as well as the safety of data information, is ensured.

5.Information-based technology: the gigabit Ethernet is used for fast communication between the local control system and the remote information system, based on which the OCP, ERP and other information-based technologies are built, in an effort to bring more benefits to our customers. Then, data will be another effective profit point for enterprise management of the customers, and economic profit will be obtained from management itself.

6.Several advanced techniques: gas-phase recover, liquid-phase closing, bottom loading, current curve control and other advanced loading techniques are adopted, to ensure a safer, more accurate and more effective loading process.

7.Several advanced devices: the international edge-cutting devices, like the batch controller of the trading handing over level meeting the highest API level, the high-precision mass flowmeter of trading handing over level, numerical control valve, V-type regulating valve of high reliability, are used during loading process. This way, advanced equipment and technologies became the No. 1 productive force.

Data management & mining technology: as for information generated during loading process control, the modern software data management & mining technology is used to reveal its inner value, and to provide effective data support for production and operation of the enterprise. This aims to eliminate blind spots in previous operation and production site management of the enterprise.

We provide a complete set of ECP engineering service involving design, supply, installation guidance, commissioning, and startup of hardware, software and onsite instrument of TLS system. Besides the automatic control scheme, other special system functions could be provided for the users as they required.

We provide engineering management and engineering service for the entire project based on the modern project management concept, so as to provide a satisfactory“turnkey”project for our users.

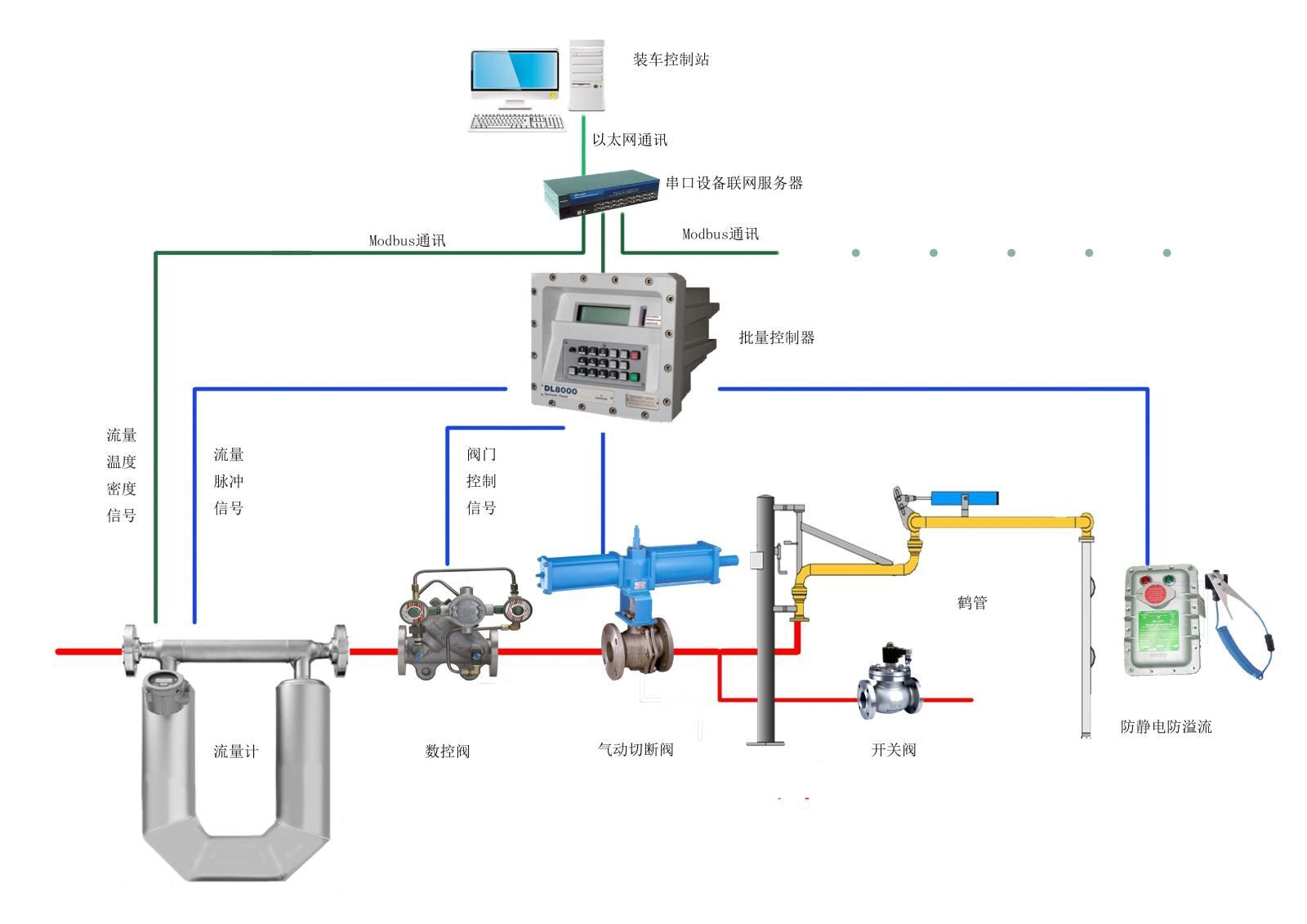

Structure system

Equipment composition:

Each loading arm position is equipment with a flow meter, a loading control valve, a static electricity protection earthing switch, an anti-overflow liquid level switch, and other accessories.

Each loading arm position is equipped with an explosion-proof batch controller.

A high-precision electronic scale (optional).

A set of loading business station and software are provided in the loading business room. A set of operation station and its software are provided in the loading control room.

Software-based control

The control design of the entire system is the core of the system. Types of control include:

Onsite distributed control layer

The onsite distributed control layer mainly consists of the batch controller and other controllers within the loading area.

The batch controller is an intelligent instrument with single-chip micro-controller as the core, and it is capable of process control, ration control, anti-overflow and static electricity protection earthing linked control during the loading process. It is capable of temperature compensation and accumulation for the flow during liquid material loading.

The batch controller is connected with onsite instrument, and it executes the monitoring and loading control functions. During independent operation of the batch controller, operators could set, operate and monitor condition for loading on site. During networked operation, the batch controller connects with the management-level computer through the communication cable, for centralized real-time management of onsite information.

Onsite test execution instrument layer

Onsite instrument includes: mass flowmeter, stop valve (these two items are to be purchased by the buyer); V-type ball valve, oil overflow electrostatic protection, explosion-proof junction box, etc. The terminal automatic loading system needs the following onsite testing and execution instrument: flow meter, thermal resistor (used when the volume flow meter is used), loading control valve, static electricity protection earthing switch, anti-overflow liquid level switch, explosion-proof alarm indicator, flame-proof type non-contact IC card reader, high-precision electronic car scale, and high-precision electronic rail scale.

Upper computer management layer

The upper computer management layer involves the special loading management software provided for the industry-level computers. Specifically, the business station is responsible for executing sales management directly related to loading. The operation station is responsible for real-time monitoring. Meanwhile, related information could be transmitted to various terminals of the Company’s information network through Ethernet.

Major functions

Screen display: loading close-up view and single-vehicle figure show the on/off status of the pumps, flow meters and valves at the loading arm positions during actual loading; related parameters of the preset loading and actual loading, alarm display, record display and menu operation;

Loading control function: the system gives loading business authorization and carries out ration loading for each loading arm position, and controls the starting and ending of loading at each loading arm position;

Alarm: sounds, voice, diagram form and other alarming methods;

Operation management: setting multi-level command and saving operation record; restriction on commands of various levels alternating the system parameters;

Network functions: It could be networked with MES and ERP systems, and provide real-time loading data for them;

On-line configuration: It allows for alternation of interface and parameters of the system during continuous operation.

Report generation and printing: configuring and making reports, generating reports automatically, and printing reports at regular intervals or as required;

Database management: It provides the loading database to allow uses to retrieve information and carry out data survey. It also provides various statistical reports, and provides powerful measures for automated management; remote end database could be used via ODBC.

Self-diagnosis: The system could carry out self-diagnosis on the system equipment automatically and give alarm in case of any abnormality.

System maintenance: The system has an online equipment drawing, processing equipment drawing and a terminal drawing, which allow users to view the system equipment status.

Major functions:

The automatic loading system of the terminal executes mainly the following functions: ration loading, security guarantee, business management and operation management.

Ration loading: The batch controller collects the signals from flow meters, and controls the loading valves via programs to realize ration control.

Security guarantee: The batch controller monitor stops the operation via controlling the pumps and valves once it senses action of the anti-overflow liquid level switch or static electricity protection earthing switch; or it stops the operation via controlling the pumps and valves once it senses action of the static electricity protection earthing switch.

Business management and operation management: It is able to carry out related sales survey, billing and business management related directly to loading, and provide real-time monitoring over the site. It also allows for IC card identity verification and access control.

Technical performance indexes

Main technical and performance indexes:

A serial communication product integrating TCP\IP, and Modbus RS485

A multi-loading-valve product allowing for use of double-section ball valve, numerical control valve and V-type adjusting ball valve

It allows for use of LNG\C4\ ethylene\ gasoline gas-phase recovery, heavy oil heat preservation, common liquid enclosed loading and other loading techniques

It allows for use of anti-static devices, anti-overflow devices, onsite emergency stop, system software emergency stop and other safety interlocks.

It allows for use of various information management systems like OPC, ERP and MIS.

It allows for use of the high-volume database system, and allows for view of onsite record data for 1 year, and permanent preservation and view of offline data.

If integrates functions like thunder proofing and pulse proofing for the onsite equipment, and protects the onsite equipment of users against damage.

It ensures a loading precision of 0.15%, which meets the domestic and international trading handing over requirements. It could be directly applied for trade handing over.

Other indexes:

Operation temperature: -20℃~60℃;

Explosion-proof grade: ExDIIBT4 Protection grade: IP65

Power supply:AC220V/DC24V

Communication:TCP\IP、Modbus RS485

Input/output:DI/AI/PI/DO/AO

Application

Major goals

Loading control and barrel filling control of small loading arm trains and tank-trucks;

Ration control of loading and barrel filling;

Interlocked control of the anti-overflow device and static electricity protection earthing device;

Metering of loading media;

Anti-water-attack measures;

Loading business management and operation management;

Loading sales survey, billing and management

add:上海市闵行区浦江镇联航路1188号 浦江智谷商业园10号楼1楼A座

邮 编:201112

传真:+ 86 21 5851 5222

邮箱:info@keypoint.cn

add:上海市闵行区浦江镇联航路1188号 浦江智谷商业园10号楼1楼A座

邮 编:201112

传真:+ 86 21 5851 5222

邮箱:info@keypoint.cn

上海敬邦机电设备有限公司版权所有

Copyright©2013 KEYPOINT Controls. All Rights Reserved